METHOD FOR THE PRODUCTION OF SINGLE - CRYSTAL c-BN POWDERS

cBN powders, featuring high hardness (Knupp

hardness up to 50 GPa) and thermal stability (up to 14000 C in argon and up to

8500 C in air), chemically inert to iron, nickel, and cobalt, are widely

applied in tools for machining high-speed, hard-to-machine, and hardened steels (HRC up to

60).

cBN powders, featuring high hardness (Knupp

hardness up to 50 GPa) and thermal stability (up to 14000 C in argon and up to

8500 C in air), chemically inert to iron, nickel, and cobalt, are widely

applied in tools for machining high-speed, hard-to-machine, and hardened steels (HRC up to

60).

The principal line of worldwide research in this area is the production of crystalline cBN powders of homogeneous structure and with high content of isometric grains. This is due to the necessity of providing guaranteed stability of physical-mechanical and thermal-physical properties, hence, of providing high reliability of tools.

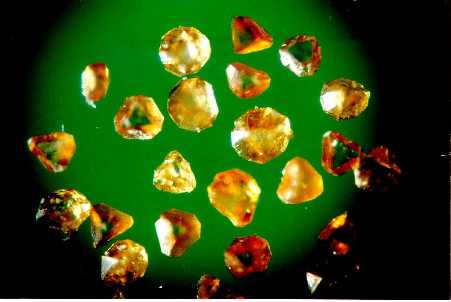

In the Institute for High Pressure Physics, monocrystal cBN powders are produced under high pressures and temperatures with the use of fluid catalyst systems. The powders are comprised of 160/100 and 100/50 m m grain-size monocrystals of tetrahedron shape, ranging in color from colorless to amber, without visible (at 32x) inclusions. The content of isometric crystals amounts to 20%. The powders are produced in a high pressure apparatus of “CONAC” type, designed in the Institute for High Pressure Physics. The one-cycle yield of the product is 2.5 carats in the reaction volume of 0.7 cm3. Physical-mechanical and thermal-physical properties of the product correspond to the best world’s powders of the same grain-size.

Monocrystal cBN powders can be used for making ceramic- and metal-bonded grinding wheels, and honing sticks to machine cast irons, and steels, including high-speed, hardened, and alloyed ones.

Contact person: Dr. Valentin Ryzhov. E-mail: ryzhov@hppi.troitsk.ru

~ About HPPI ~ Scientific divisions ~ Scientific

activities ~ Our products ~

~ Office of the director ~